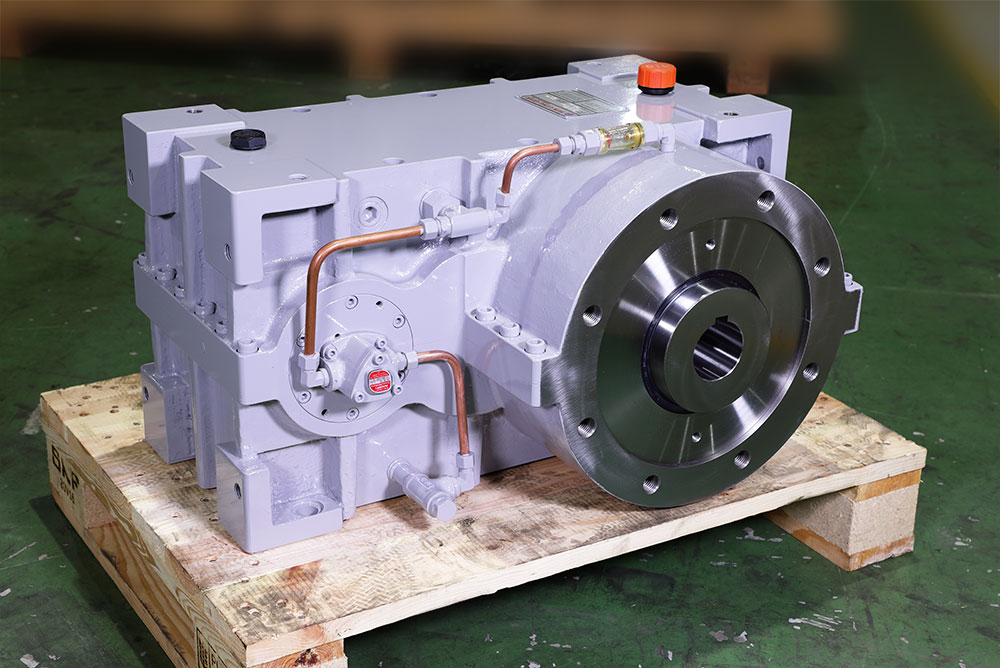

Sterling Extruder

Precision Rebuilding • Reverse Engineering • Performance Optimization

IMR specializes in rebuilding and remanufacturing Sterling extruder gearboxes, ensuring reliable operation, extended service life, and consistent high performance in demanding extrusion applications.

WHAT WE SERVICE

- All Sterling single-screw and twin-screw extruder gearboxes

- High-torque and high-load models

- Gear trains, helical gears, and thrust assemblies

- Gearbox housings, bores, endplates, and bearing fits

- Shafts, keys, and output assemblies

- Cooling system components

OUR REBUILDING PROCESS

1. Full Teardown & Evaluation

- Crack inspection and wear analysis

- Gear and bearing evaluation

- Alignment, center distance, and backlash check

- Lubrication system assessment

2. Precision Remanufacturing

- Shaft replacement or machining

- Reverse engineering of obsolete components

- Oversize bearing bore machining

- Gear grinding and tooth profile correction

- Housing weld-repair and machining to OEM standards

3. Assembly & Testing

- Bearing preload and gear mesh set to spec

- Load testing under operational conditions

- Final inspection and performance certification

ADDITIONAL SERVICES

- Rush rebuilds and emergency service

- Free pickup & delivery nationwide

- Vibration and alignment verification

- Oil system cleaning and filtration support

COMMON FAILURE INDICATORS

- Excessive noise or vibration

- Overheating or abnormal oil temperature

- Metal particles in oil

- Shaft or bearing play beyond tolerance

- Gear wear or misalignment

WHY IMR

- Expert in all Sterling extruder gearbox models

- Fast turnaround with OEM-level precision

- Reverse engineering for obsolete parts

- Proven reliability across extrusion applications

- Full IMR warranty for rebuilt gearboxes