About Us

About Us

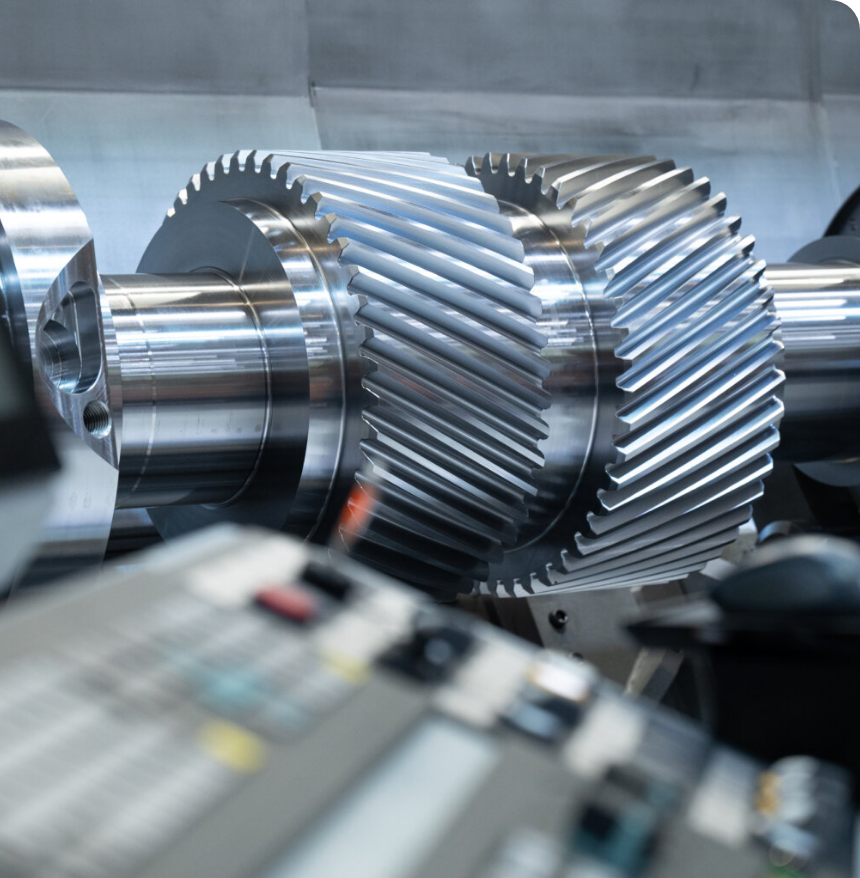

Delivering Precision, Reliability, and Industrial Excellence

At Lone Star Machine Shop, we help industrial operations stay productive, efficient, and profitable. With more than 20 years of hands-on experience, we specialize in industrial equipment restoration, surface engineering, gear rebuilding, and precision machining to keep operations productive and profitable.

Our team understands how critical reliable machinery is to daily operations. That’s why every service we deliver focuses on precision workmanship, consistent performance, and long-term value.

Built on Experience You Can Trust

We Understand Your Equipment Inside and Out

Industrial machinery requires expert care, not shortcuts. Our technicians have decades of experience managing legacy machinery repair services.

From routine evaluations to complex component restoration, we restore confidence in equipment performance while supporting emergency industrial equipment repair. We don’t just repair parts; we regain confidence in your equipment.

Happy customers

Perfect reviews

Natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam.

Company Overview

Lone Star Machine Shop specializes in high-quality gear rebuilding services, advanced multilayer industrial coatings, & high-precision repairs to OEM specifications. Our company is filled with modern machining technology and supported by skilled professionals who understand the demands of industrial performance.

Whether you need to restore worn components or improve operational efficiency, we offer cost-effective solutions that don't compromise quality.

Experience & Technical Expertise

Our repair process relies on thorough inspection, detailed analysis, and precise execution. We manage:

- Detailed machinery inspections

- Reverse engineering industrial parts even without drawings

- Precision machining and rebuilding

- Performance optimization for demanding environments

Our work varies from individual components to complete machinery systems, all designed for durability and reliability.

Pricing & Turnaround

Fast, Fair, and Focused on Your Operations

We know that downtime directly impacts revenue. As a result, we offer fast turnaround repair services tailored to your operational schedule at competitive rates.

Our goal is simple: restore functionality quickly while delivering repairs that last.

Cost Savings & Long-Term Benefits

By choosing repair and restoration over complete replacement, our clients often save up to 50% on equipment costs. Beyond savings, our services help:

- Minimize unplanned downtime

- Improve production efficiency

- Extend machinery lifespan

- Reduce future maintenance risks

We prioritize clear communication and dependable service from start to finish.

Our services

Precision Solutions for Industrial Machinery

Gear Rebuilding

Reverse Engineering

Machinery Inspections

Edge Services

Why Choose Lone Star Machine Repair

- Over 20 years of industry experience

- Skilled technicians with hands-on expertise

- Proven cost-saving repair strategies

- Reliable turnaround times

- Support for both new and legacy equipment

We take pride in delivering solutions that keep your operation moving.

Frequently asked questions

What types of equipment do you repair and service?

We repair and restore critical industrial machinery components used across manufacturing, energy, and heavy industrial sectors, supporting both modern and older equipment.

Do you offer repair solutions instead of complete equipment replacement?

Yes. Our services are designed to extend equipment life and reduce replacement costs whenever repair is a viable option.

What repair services do you provide?

Our services include gear rebuilding, reverse engineering, machinery inspections, edge services, and advanced surface coatings.

How do you ensure repair quality and reliability?

Every project follows strict inspection standards, precision machining processes, and quality checks to ensure long-term performance.

Can repairs be customized for specific operational needs?

Yes. We create customized solutions based on equipment usage, load conditions, and production requirements.

Ready to Restore Performance?

Lone Star Machine Repair is committed to keeping your machinery reliable, efficient, and production-ready with trusted industrial machinery repair practices focused on long-term performance.

Get in touch with us today to learn how our targeted solutions can help you maintain stable operations and control costs.